Are you struggling to keep your manufacturing operations organised and efficient? Manufacturing ERP software helps manufacturers plan, manage, and deliver specific features supporting various business operations.

In day-to-day operations, there's a lot of reporting and data gathering, which needs careful management. The goal is to have a system that ensures information flows smoothly and uniformly, following clear codes and procedures.

Testing is crucial for a successful ERP system implementation. Continuous testing helps identify problems and ensures quality delivery across business processes.

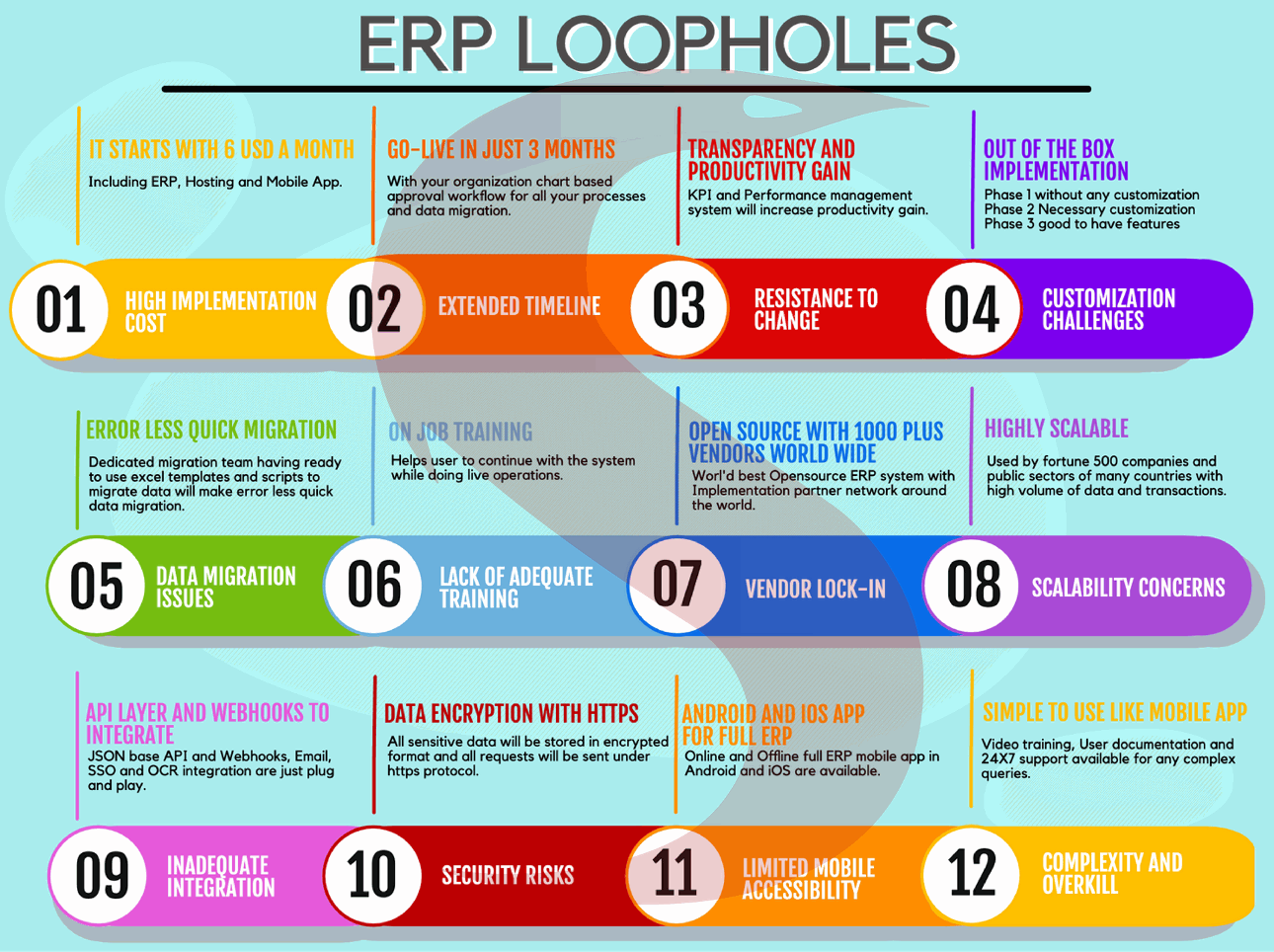

This article will discuss why fixing ERP loopholes in manufacturing is important and how to keep operations running smoothly without errors.

1. High Implementation Cost

The financial commitment required for ERP implementation is substantial. Beyond purchasing the software, companies must budget for hardware, training, and ongoing maintenance costs. This significant upfront investment demands careful planning and justification to ensure a return on investment.

Solution: Choose affordable ERP options or introduce the system gradually to spread out expenses. There are several cost-effective ERP implementation services that start at just $6 a month, covering ERP, hosting, and a mobile app.

2. Extended Timeline

ERP projects are notorious for extending beyond their projected completion dates. Factors such as data migration complexities, customisation requirements, and employee resistance contribute to these delays, disrupting the anticipated timeline for achieving productivity gains.

Solution: Improve project management and simplify implementation to meet deadlines. Go live in just three months by using your organisation's chart-based approval workflow for all processes and data migration.

3. Resistance to Change

Adopting a new ERP system is not an exception to the general rule that people resist change. Employee resistance to new processes would hinder the change and lessen the expected productivity benefits since workers who are used to antiquated practices would find it difficult to adopt new ones.

Solution: Use change management strategies and thorough training programs to smooth the transition. A KPI and performance management system will also help you gain transparency and boost productivity.

4. Customisation Challenges

ERP systems are very customizable and scalable, yet adapting them to specific business requirements might be difficult. The intricacy of personalization may result in longer lead times and higher expenses.

Solution: Choose ERPs that are easy to customise or adapt business processes to fit ERP functionalities. Implement in phases:

Phase 1 - without any customisation

Phase 2 - with the necessary customisation

Phase 3 - with additional features as needed.

5. Data Migration Issues

The process of moving data from outdated systems to a new ERP is difficult yet necessary. Errors that occur during the ERP Migration process might affect the data integrity in the new system and create delays.

Solution: Use specialised ERP data migration tools and services for a smooth transfer of data. Achieve error-free and quick migration with a dedicated team equipped with ready-to-use Excel templates and scripts.

6. Lack of Sufficient Training

For employees to utilise the ERP system effectively, they need to get the appropriate training. Underutilization might impede the advantages of the system due to inadequate or neglected training.

Solution: Increase investment in employee training programs to ensure they can use the ERP Training system effectively. On-the-job training helps users continue using the system while performing live operations.

7. Vendor Lock-in

Dependency on a single vendor for ERP products and services can be restrictive and expensive in the long run. It's critical to consider vendor lock-in when choosing an ERP system.

Solution: Select vendors that offer flexibility and avoid committing to long-term contracts whenever feasible to avoid dependency. Opt for open-source solutions with over a thousand vendors worldwide, providing access to the world's best ERP system along with a global network of implementation partners.

8. Scalability Concerns

Despite ERPs being designed for scalability, some businesses encounter difficulties in expanding their systems to accommodate growth, often due to the system's complexity or vendor constraints.

Solution: Choose scalable ERPs that can expand along with your business requirements. Fortune 500 companies and public sectors in many countries utilise these highly scalable systems, handling large volumes of data and transactions.

9. Inadequate Integration

Having multiple units and systems scattered across different locations in your manufacturing company can cause problems like poor information flow, coordination issues, and data silos. This makes it hard to put basic procedures in place.

Solution: Integrate seamlessly with the API layer and webhooks. Simply plug and play with JSON-based API, webhooks, email, single sign-on (SSO), and optical character recognition (OCR) integration.

10. Security Risks

In an era where data security is paramount, any vulnerability in an ERP system can expose sensitive information, posing significant risks to the organization.

Solution: Enhance security measures by selecting secure vendors and conducting regular security audits. Ensure data encryption with HTTPS protocol, where all sensitive information is stored in an encrypted format, and all requests are transmitted securely.

11. Limited Mobile Accessibility

The demand for mobile accessibility is higher than ever, yet some ERP systems fall short of providing comprehensive mobile access, limiting real-time decision-making capabilities.

Solution: Make sure the ERP allows mobile access or create custom mobile apps for smooth usage. Full ERP mobile apps, offering online and offline functionality, are available for Android and iOS.

12. Complexity and Overkill

Implementing an extensive ERP system may introduce unnecessary complexity if it's not aligned with the business's actual needs, leading to inefficiency and wasted resources.

Solution: The system offers intuitive usability for users seeking simplicity akin to their favorite mobile apps. Users can access video training, comprehensive user documentation, and 24/7 support to address any complex queries they encounter.