Managing a meat processing business is very challenging at present. Owing to its requirement to ensure the quality of the product, maintain cold storage, and meet all the compliance requirements. Just imagine how convenient it would be if you could manage it all from a single platform?

The meat industry requires a solution that can help to align every stage of the operation, like procurement, production, quality checks, packaging, storage, sales, and accounting, into a single screen.

Nowadays, organizations need tracking, visibility in real-time, and cost control, from raw materials to the packaged product. That’s where ERP solutions like Odoo come in.

➣ Pain Points & Solutions – Odoo ERP for Meat Processing Industry

1️) Lack of End-to-End Traceability

Pain Point:

The majority of the meat processors struggle to trace goods from livestock to the final packaged item. When there’s a quality issue or product recall, tracking the source becomes time-consuming.

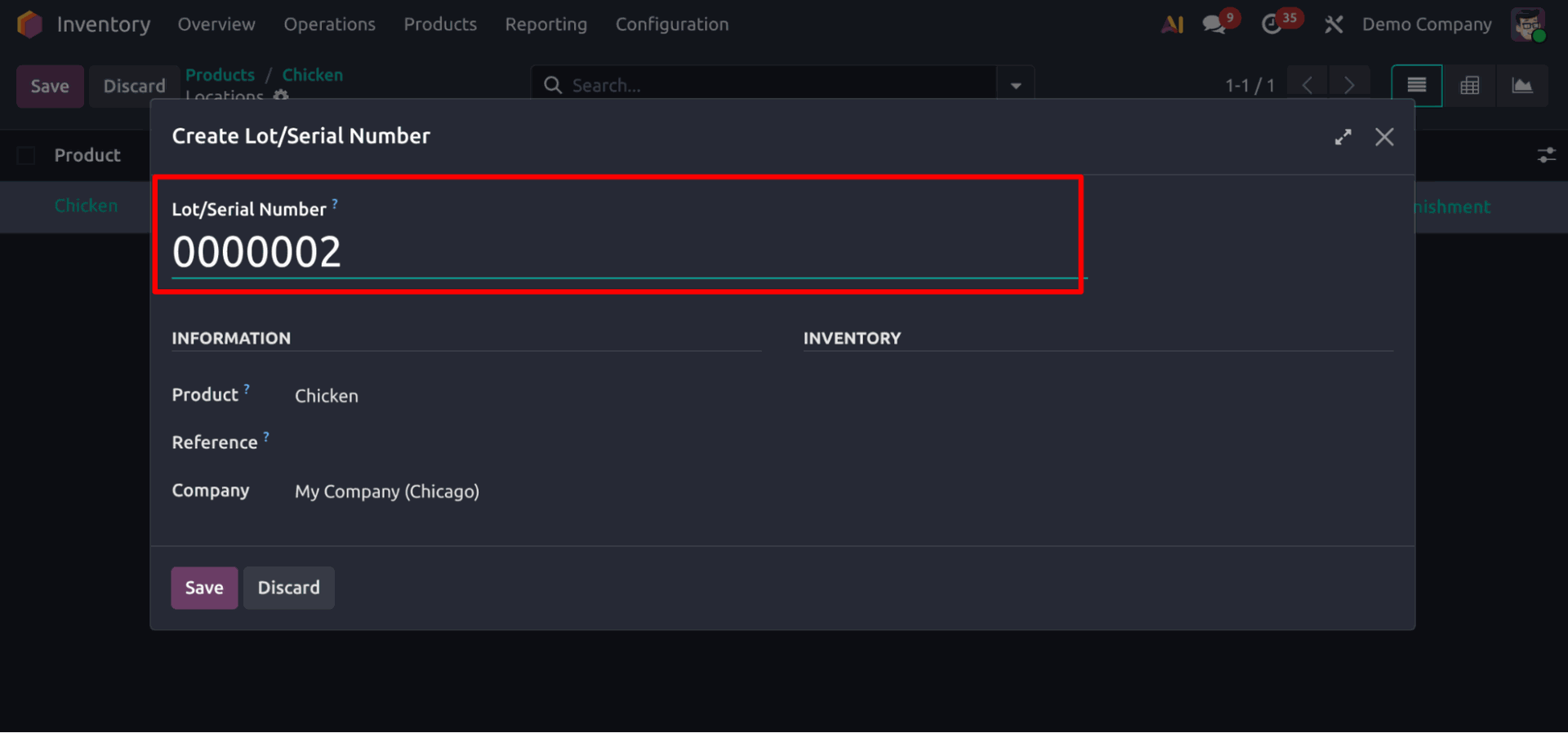

Odoo Solution:

Odoo ERP provides lot & serial number tracking at every stage, from processing, packaging, to sales and delivery of livestock intake. This will ensure complete traceability and compliance with food safety standards for HACCP and FSSAI.

2️) Disconnected and Manual Processes

Pain Point:

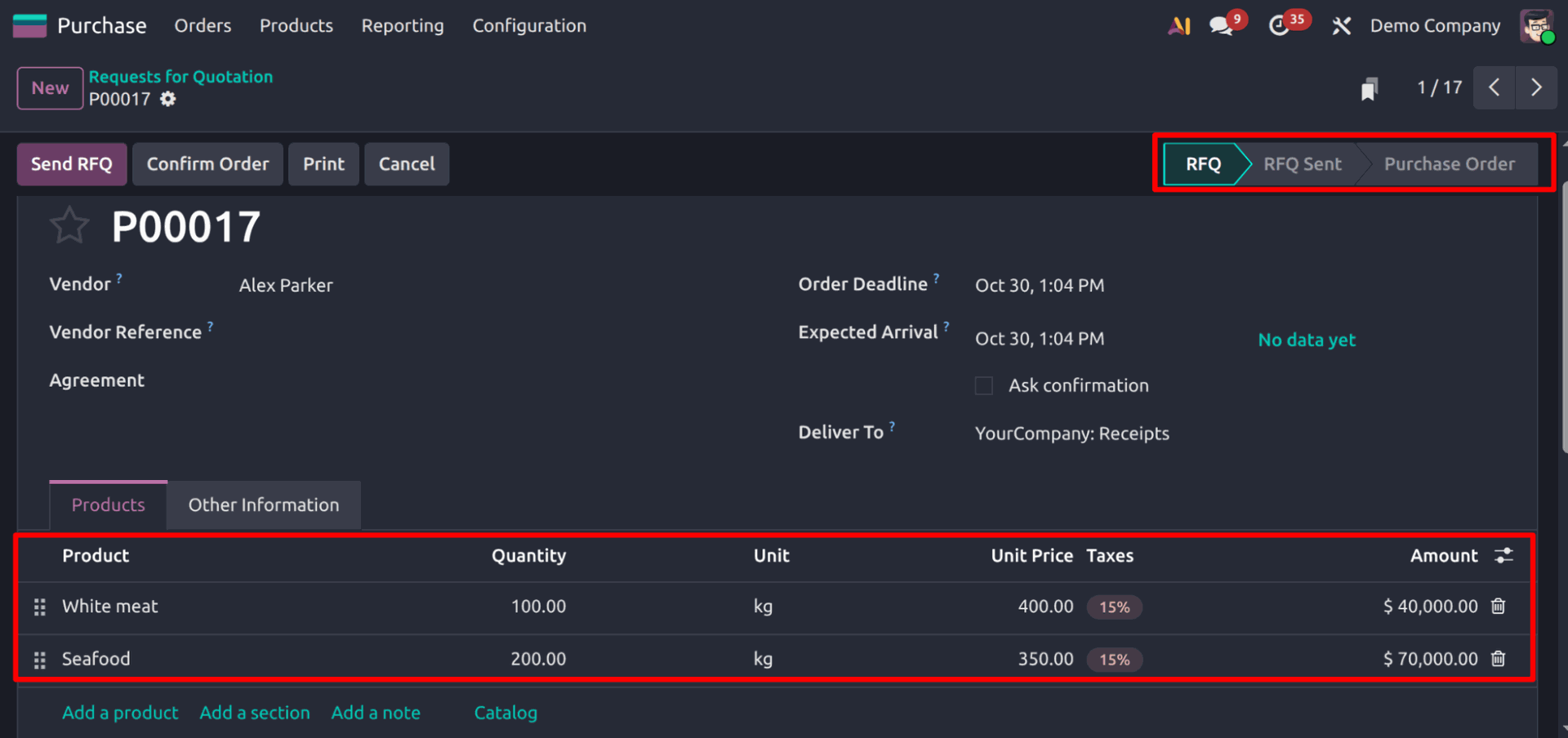

Different Stages, like procurement, production, inventory, and accounting, often work separately, which leads to duplicate entries, delayed data updates, and poor coordination.

Odoo Solution:

Odoo unites all operations under a single integrated system. Purchases, inventory, production activities, and accounts are linked automatically, giving actual time visibility and removing physical errors.

3 ) Wastage Tracking

Pain Point:

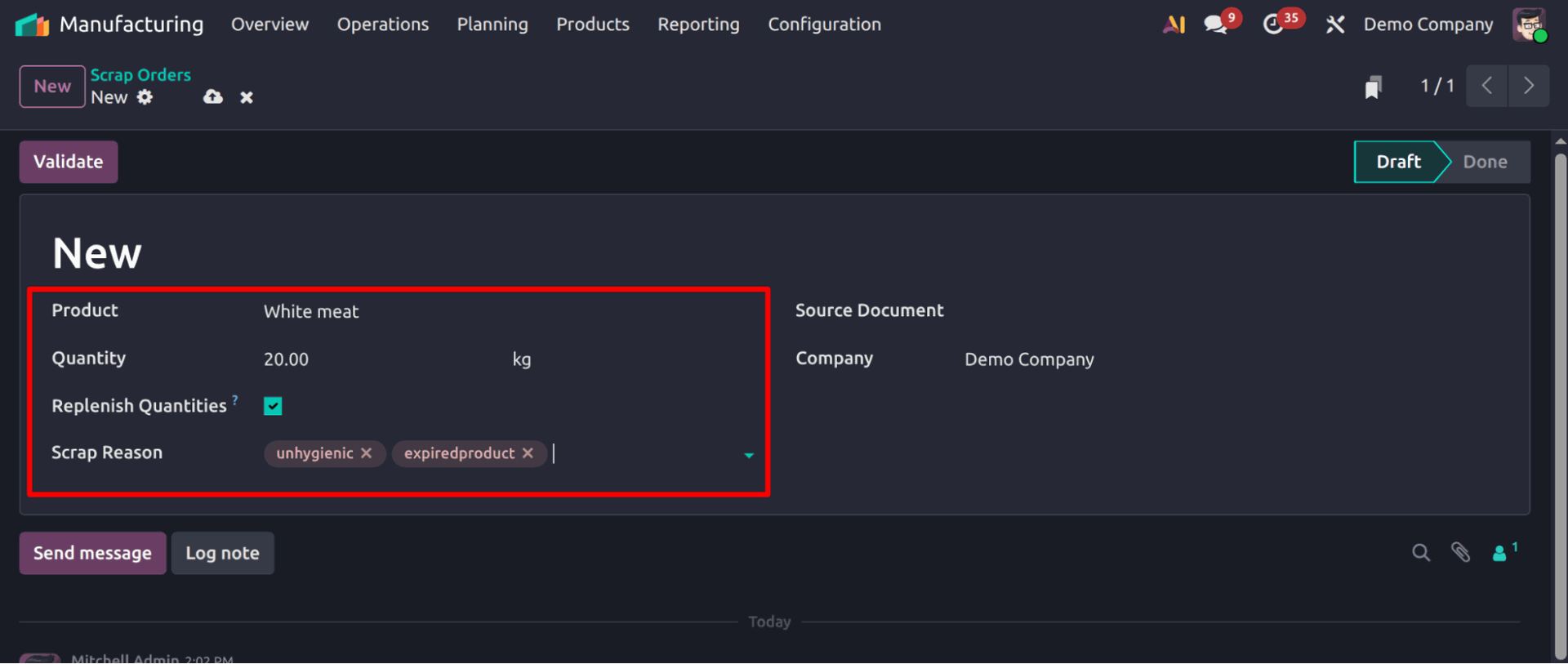

It is difficult to monitor the difference between live weight and processed weight. Without accurate data, managers can not identify losses or inefficiencies.

Odoo Solution:

Odoo’s Manufacturing (MRP) module automatically records yield percentages, manages by-products like fat, bone, and hide, and helps you compare actual output with expected results to reduce wastage.

4️) Complex Quality and Compliance Requirements

Pain Point:

Regulatory documentation, maintaining hygiene checks, and temperature logs by hand can result in missed inspections or compliance failures.

Odoo Solution:

The Quality module here activates automated quality control points during every process from cutting to packaging. It stores inspection results, temperature readings, and certificates digitally, ensuring easy audit readiness.

5️) Cold Storage/Temperature Monitoring

Pain Point:

Without proper temperature tracking, products risk spoilage, leading to financial and brand losses.

Odoo Solution:

Odoo can monitor cold storage temperature in real time, alerting you instantly when it goes beyond safe limits, protecting stock and maintaining freshness. With the help of IoT integration,

6️) Unclear Costing and Profitability

Pain Point:

Businesses often lack visibility on actual costs per batch or per kilogram, making it hard to manage margins and pricing.

Odoo Solution:

The manufacturing module helps to calculate production costs, which include the raw materials, labor, and overhead. This provides precise insights into expenses and helps set profitable target pricing strategies.

7️) Stock Visibility and Expiry Control

Pain Point:

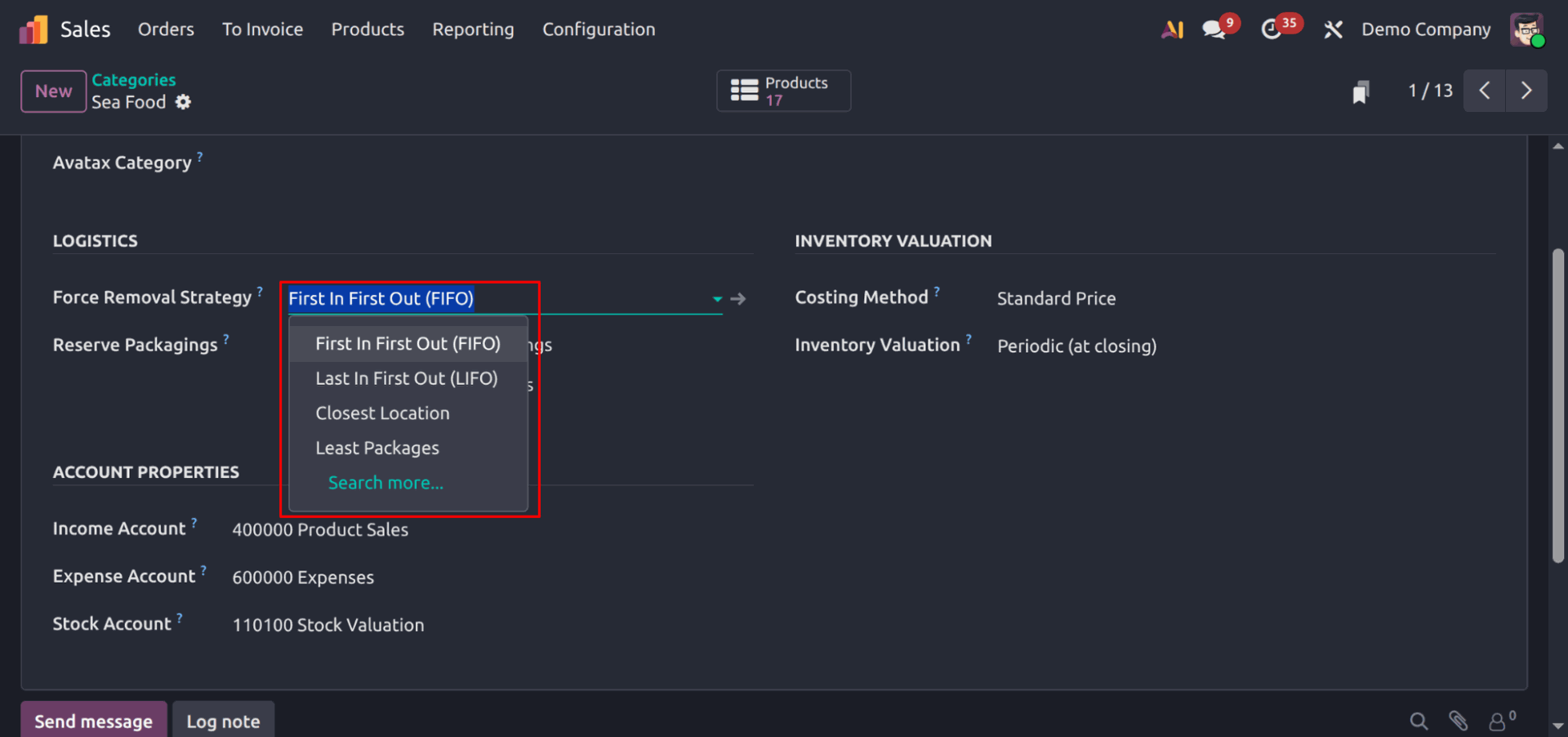

Unplanned Overstocking, understocking, as well as expired products can severely impact profitability.

Odoo Solution:

With lot tracking and expiry date management, Odoo ensures products move according to FIFO or LIFO rules, helping maintain optimal stock and reducing waste.

8️) Delayed Sales and Distribution

Pain Point:

Manual sales order entry and delivery scheduling often slow down fulfillment.

Odoo Solution:

From inquiry, quotation, and order confirmation to delivery and invoicing, it can automate your entire business sales cycle. This will help to streamline your operations and make sure faster customer service.

9️) Machine Downtime

Pain Point:

Unplanned maintenance of processing machines disrupts production schedules.

Odoo Solution:

Odoo has a Maintenance module that helps the organization plan preventive maintenance for all necessary equipment, minimizing downtime and improving equipment efficiency.

10 ) Limited Data Visibility and Reporting

Pain Point:

Usually, decision-makers feel a shortage of real-time data on production efficiency, wastage, or profitability.

Odoo Solution:

Odoo provides interactive dashboards and analytics that display yield %, stock age, cost breakdowns, and profit reports, which enable data-driven decisions across the business.

➣ Key Summary

Odoo ERP is more than just a management system, it can become a digital backbone for the meat processing industry. With Odoo, we can automate our entire business, streamline our production, and improve our firm's profitability with efficiency.

For achieving higher returns, reducing wastage, and getting full traceability, driving efficiency and profitability, Odoo is the solution you have been looking for. To know more about the Odoo implementation plan for your Meat and poultry industry, connect with us at contact@serpentcs.com